Retrofit An Elevator To Replace Your Manlift

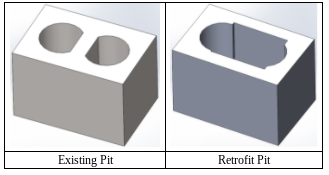

A proposal was made by Humphrey Manlift for Market in retrofitting 350 lb. cage lift elevator assemblies in replacement of aging man lifts. The existing man lift pits will need to be slightly modified to accommodate the elevator assembly. If you need a little help, take a look at our Glossary of Elevator Terms.

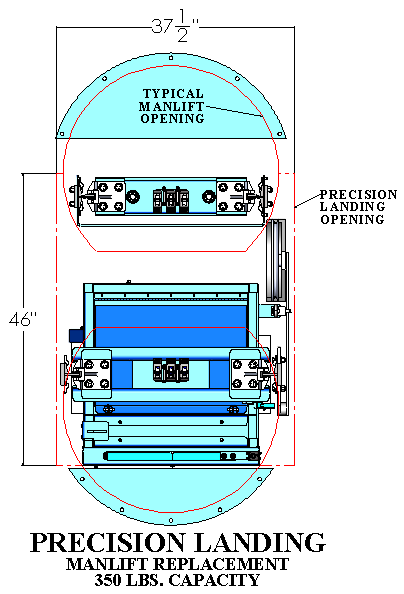

A 46″ x 37-1/2″ box will need to be cut into the existing area of the pit for this accommodation.

The elevator assembly components must be caged-in at each floor in order to comply with current ANSI (American National Standards Institute) standards. A bolt-together, 4-piece cage was designed to surround the elevator assembly in order to comply with these standards. The framework of the cage is constructed of 2×2 square tubing with bolt-on 12 GA. sheet metal skins. Each frame weldment will bolt together using four 3/8″ bolts at each corner. The front of the cage utilizes the same door as used in the hoistway tower applications.

The door and frame have been designed to accommodate both right-hand and left-hand swing applications.Due to the round geometry of the existing manlift pit and floor openings, there will be openings at the front and back of the elevator assembly in which the cage framework will not cover. To solve this issue, a simple plate will anchor the floor of each landing to cover the holes.

Retrofitting A New Precision Landing Technical Drawing